Metal Additive Manufacturing in Orbit

Improving a miniature 3D printer for orbital experiments

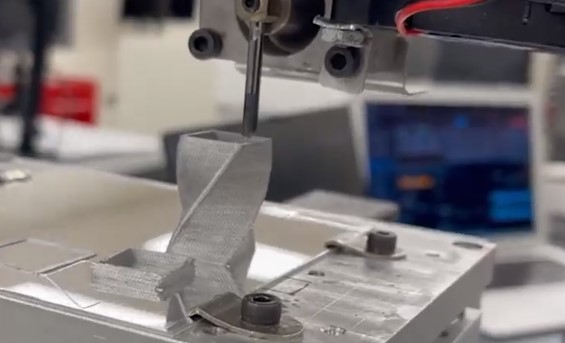

My master’s applied project was working at an ASU Polytechnic research lab to develop a new version of a 3D printer. The lab is working on metal additive manufacturing at low temperature, I was brought on the team to build a new frame for the miniature printer that has the proper form factor for an experiment in orbit. See this LinkedIn post for a video of the process.

I was able to increase the rigidity, modularity, power, and speed of the system. My design for the printer used fewer custom parts by sharing parts between multiple subsystems, allowing some features to go unused depending on the specific application. This allowed for fewer manufacturing drawings and a simpler machine. I also used my machining background to design many of the parts to require as little material removal from stock raw material sizes, further reducing cost as there is less material waste. This went along with minimizing the different types of screws to reduce assembly time. I also researched and selected the electronics and motion hardware needed for the demanding requirements of the application.